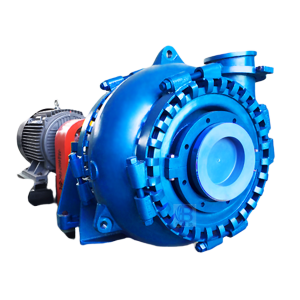

TSP/TSPR vetikal slurry mgbapụta

TSP/TSPR vetikal slurry mgbapụtae mere maka ngwa chọrọ ukwuu pụrụ ịdabere na anwụ ngwa ngwa karịa ot vetikal usoro nfuli nwere ike inye.Elastomer zuru oke ma ọ bụ ígwè siri ike dabara adaba.Ọnweghị bearings ma ọ bụ mbukota mmiri.Ikike dị elu imewe mmiri okpukpu abụọ.Ogologo imi mmiri ahaziri ahazi yana ihe mgbata mmiri dị.The TSP/TSPR vetikal sump mgbapụta dabara adabara arọ na-aga n'ihu na-ejizi abrasive na corrosive mmiri mmiri na slurries mgbe imikpu n'ime sups ma ọ bụ olulu.

Atụmatụ imewe

√ Obere iyi, obere corrosion

Ngwa ndị wetted dị n'ọtụtụ alloys na elastomers, nke Weir Minerals na-ahọrọ ngwakọta kachasị mma nke ihe maka oke nguzogide iyi n'ihe fọrọ nke nta ka ọ bụrụ ngwa ụlọ ọrụ ọ bụla, gụnyere ndị na-achọ ma abrasion na nguzogide corrosion na ebe oke irighiri ma ọ bụ nnukwu njupụta slurries. na-ezute.

• Alloy A05 Ultrachrome® na-eguzogide abrasion.

• Abrasion/corrosion na-eguzogide A49 Hyperchrome® alloy.

• igwe anaghị agba nchara na-eguzogide corrosion.

• eke na sịntetik elastomers.

√ Ọ nweghị ndagide ebili mmiri

Oghere cantilever siri ike na-ezere mkpa ọ dị n'ime mmiri dị ala - nke na-abụkarị isi iyi ọdịda akaghi aka.

• Igwe ihe eji arụ ọrụ dị arọ, n'elu efere mgbago.

• Ọnweghị bearings imikpu.

• Nchedo na-ebu labyrinth/flinger.

• Isi ike, nnukwu ogwe dayameta.

√ Enweghị nsogbu akara akara

Nhazi cantilever kwụ ọtọ achọghị akara aro.

√ Ọ dịghị priming chọrọ

Nhazi ntinye nke elu na ala dabara adaba maka ọnọdụ "snore".

√ Obere ihe ize ndụ nke igbochi

Inlets ndị a kpuchiri ekpuchi na nnukwu oghere impeller na-ebelata ohere nke mgbochi.

√ Ọnụ ego mmiri enyemaka efu

Nhazi cantilever kwụ ọtọ na-enweghị gland ma ọ bụ n'ime mmiri dị n'ime mmiri na-ezere mkpa nke gland dị oke ọnụ ma ọ bụ na-ebu mmiri.

TSP/TSPRPump Slurry kwụ ọtọs Performance Parameters

| Nlereanya | Ike dakọtara P (kw) | Ike Q (m3/h) | Isi H (m) | Ọsọ n (r/min) | Eff.η (%) | impeller dia. (mm) | Ihe kacha (mm) | Ibu (kg) |

| 40PV-TSP(R) | 1.1-15 | 7.2-29 | 4-28.5 | 1000-2200 | 40 | 188 | 12 | 300 |

| 65QV-TSP(R) | 3-30 | 18-113 | 5-31.5 | 700-1500 | 60 | 280 | 15 | 500 |

| 100RV-TSP(R) | 5.5-75 | 40-289 | 5-36 | 500-1200 | 62 | 370 | 32 | 920 |

| 150SV-TSP(R) | 11-110 | 108-576 | 8.5-40 | 500-1000 | 52 | 450 | 45 | 1737 |

| 200SV-TSP(R) | 15-110 | 180-890 | 6.5-37 | 400-850 | 64 | 520 | 65 | 2800 |

| 250TV-TSP(R) | 18.5-200 | 261-1089 | 7-33.5 | 400-750 | 60 | 575 | 65 | 3700 |

| 300TV-TSP(R) | 22–200 | 288-1267 | 6-33 | 350-700 | 50 | 610 | 65 | 3940 |

TSP/TSPRPump Slurry kwụ ọtọs Ngwa

The TSP/TSPR verical slurry nfuli dị n'ụdị dịgasị iche iche nke ewu ewu na-adabara ọtụtụ ngwa mgbapụta.The TSP/TSPR sump pumps na-egosi na ha nwere ntụkwasị obi na arụmọrụ zuru ụwa ọnụ na: nhazi nke mineral, nkwadebe coal, nhazi kemịkalụ, njikwa nsị, ájá na gravel na ihe fọrọ nke nta ka ọ bụrụ ihe ọ bụla ọzọ tank, olulu ma ọ bụ oghere-na-na ala slurry njikwa ọnọdụ.The TSP/TSPR mgbapụta imewe na ma ike metal (TSP) ma ọ bụ elastomer kpuchie (TSPR) components na-eme ka ọ dị mma maka abrasive na / ma ọ bụ corrosive slurries, nnukwu urughuru nha, elu njupụta slurries, na-aga n'ihu ma ọ bụ "snore" ọrụ, arọ ọrụ na-achọ cantilever. osisi.

* Nfuli nfuli kwụ ọtọ TSP na ihe nchekwa na-agbanwe naanị ya na nfuli slurry nke Warman® SP kwụ ọtọ.

TH Cantilevered, Herizontal, Centrifugal Slurry Pump Ihe:

| Koodu akụrụngwa | Nkọwa ihe | Ngwa ngwa |

| A05 | 23%-30% Cr Iron ọcha | Impeller, liners, expeller, expeller mgbanaka, nri igbe, akpịrịbush, frame efere liner ntinye |

| A07 | 14%-18% CR Iron ọcha | impeller, liners |

| A49 | 27%-29% Cr Carbon ọcha Ígwè dị ala | impeller, liners |

| A33 | 33% crosions & corrosion Resistance White Iron | impeller, liners |

| R55 | Rubber eke | impeller, liners |

| R33 | Rubber eke | impeller, liners |

| R26 | Rubber eke | impeller, liners |

| R08 | Rubber eke | impeller, liners |

| U01 | Polyurethane | impeller, liners |

| G01 | Ígwè isi awọ | Efere efere, efere mkpuchi, onye na-achụpụ ihe, mgbanaka mgbanaka, ụlọ ebu, isi |

| D21 | Iron ductile | Efere efere, efere mkpuchi, ụlọ ebu, isi |

| E05 | Carbon ígwè | Osisi |

| C21 | Igwe anaghị agba nchara, 4Cr13 | Ogwe aka, mgbanaka oriọna, ihe mgbochi oriọna, mgbanaka olu, bolt gland |

| C22 | Igwe anaghị agba nchara, 304SS | Ogwe aka, mgbanaka oriọna, ihe mgbochi oriọna, mgbanaka olu, bolt gland |

| C23 | Igwe anaghị agba nchara, 316SS | Ogwe aka, mgbanaka oriọna, ihe mgbochi oriọna, mgbanaka olu, bolt gland |

| S21 | Butyl Rubber | Mgbanaka nkwonkwo, nkwonkwo nkwonkwo |

| S01 | EPDM rọba | Mgbanaka nkwonkwo, nkwonkwo nkwonkwo |

| S10 | Nitrile | Mgbanaka nkwonkwo, nkwonkwo nkwonkwo |

| S31 | Hypalon | Impeller, liners, mgbanaka mgbanaka, onye na-achụpụ ihe, mgbanaka nkwonkwo, nkwonkwo akara |

| S44/K S42 | Neoprene | Impeller, liners, mgbanaka nkwonkwo, nkwonkwo akara |

| S50 | Viton | Mgbanaka nkwonkwo, nkwonkwo nkwonkwo |