Tspr roba na-agbado mmiri

Tsp ROBVetikal slurrysdị na usoro dị iche iche iji daba ama nke ukwuu, maka oke ọkpọkọ ma ọ bụ ebe dị elu na-amanye ogologo nke mgbapụta iji wesaa omimi nke mgbapụta ahụ site na mita 2. A na-edozi pumping ọbụna mgbe a naghị etinye akwa nke dị n'elu ala, si otú a na-enyere ọkwa mmiri mmiri iji belata aka nri ala ma ọ bụ ala nke ọ bụla ndọtị ọ bụla. Akụkụ mmiri nke Tspr Vetical Stump na-agbanwe agbanwe na spo usoro sporsical metal dị larịị.

Njirimara imewe

Mgbakọta na - emekọ ihe - ihe ndị a na - eme ka a na - emekọ ihe, a na - ejikọ aka na ụlọ na ụlọ na-ezere ka nsogbu jikọtara ya na arụmọrụ nke akụrụngwa nke mpaghara ọsọ mbụ.

Mgbakọ ahụ a na-ete mmanụ ma kaa ya labalyrints; A na-ete elu dị elu na ala nke flanger pụrụ iche. Igwe elu ma ọ bụ draịva na-eme mkpọtụ bụ ụdị roller dị n'okpuru ebe a na-eme obere ihe bụ ihe okpukpu abụọ nke na-ebu ụzọ na-ese n'elu mmiri. Nhazi nke a dị elu na akụrụngwa siri ike na-ewepụ mkpa nke dị ala.

Mgbakọ ndị dị nro - zuru ezu na steepụ dị nro. TSR TRY AKA NA-EGO.

Igha Igha - nwere ihe dị mfe bolt-na ntọala nke kọlụm. Emepụtara ya site na iyi na-eguzogide ọgwụ maka TSP ma site na Elestomer maka TSP.

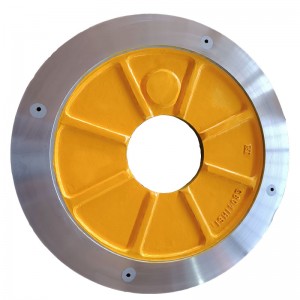

√ Debeller - okpukpu abụọ nke ndị na-eme ihe (elu na ntinye) Yiri alloys na-eguzogide ọgwụ, polyurethane na ndị na-akwado Elastomer Elastomer na-agbanwe agbanwe. A na-edozibido mbibi ahụ na-aga n'ihu n'ime nkedo n'oge nzukọ site na mkpọchi mpụga n'okpuru ụkwụ ụlọ na-emegharị ụlọ. Enweghị mmezi ọzọ dị mkpa.

Rubir Ruter - rapu-na metal metal; Snap-on elastomer ma ọ bụ polyurethane maka nfuli TSP na TSPR. Ndị na-emebi ihe dabara na mmeghe.

Look rainder - by metal ma ọ bụ polyurethane maka tsp; Snap Snap-on Elastomer maka TSPR.

√ Iwepu paịpụ - ọla maka tsp; Elastomer kpuchie maka TSPR. A na-ejigide akụkụ ọla ahịhịa niile kpamkpam.

√ Ibelata

√ Ekpere - a ga - etinye nhazi njikọ Tspray nke mpụga na mgbapụta dị ka nhọrọ. N'aka nke ọzọ, onye na-aga ọrụ na-adabere na agbatị agbatị sitere na anya na-akpata ya.

Ihe eji eme ihe - nfuli nwere ike imepụta ya na ihe na-eguzogide na-eguzogide.

Tsp ROBVetikal slurryScramers arụmọrụ

| Mogosi | Max.power p (kw) | Mezuo arụmọrụ mmiri | Dambeller Dia. (mm) | ||||

| Ike q | Isi h (m) | Ọsọ n (r / min) | Max. Effef. (%) | ||||

| m3 / h | l / s | ||||||

| 40PV-tspr | 15 | 17.28-39.6 | 4.8-11 | 4-26 | 1000-2200 | 40 | 188 |

| 65qv-tspr | 30 | 22.5-105 | 6.25-29.15 | 5.5-30.5 | 700-1500 | 51 | 280 |

| 100rv-tspr | 75 | 64.8-285 | 18-79.2 | 7.5-36 | 600-1200 | 62 | 370 |

| 150sv-tspr | 110 | 108-479.16 | 30-133.1 | 8.5-40 | 500-1000 | 52 | 450 |

| 200sv-tspr | 110 | 189-891 | 152.5-247.5 | 6.5-37 | 400-850 | 64 | 520 |

| 250TV-TSPR | 200 | 261-1089 | 72.5-302.5 | 7.5-33.5 | 400-750 | 60 | 575 |

| 300tv-tspr | 200 | 288-1267 | 80-352 | 6.5-33 | 350-700 | 50 | 610 |

TSPR ROB TUPTER VERTICE SLURD SLURS ngwa

Ntinye TSP na SP, na-emepụta ihe dị mfe, na-enye ndị dị mfe, ma ọ bụ nke na-eme mkpọtụ, na-aga n'ihu, na-aga n'ihu, ma ọ bụ ọnọdụ oghere na-ejikwa.

Mara:

Tspr rọba nke kwụ ọtọ na-agbasa na spater na-agbagha na ferranch roba slan nke vertic slurr na spar.

Cantived, kehoraizin, centrifugal slurry pọmbụ:

| Koodu ihe onwunwe | Nkọwapụta anụ | Ngwa mejupụtara |

| A05 | 23% -30% crain | Debeller, Liners, na-ere, chụpụ mgbanaka, igbe nri, akpịrịkpa, wepụta efere liner |

| A07 | 14% -18% crain | Debeller, liners |

| A49 | 27% -29% carbon carbon | Debeller, liners |

| A33 | 33% cr erhations & corrosion iguzogide ígwè | Debeller, liners |

| R55 | Roba roba | Debeller, liners |

| R33 | Roba roba | Debeller, liners |

| R26 | Roba roba | Debeller, liners |

| R08 | Roba roba | Debeller, liners |

| U01 | Polyurtane | Debeller, liners |

| G01 | E ígwè ígwè | Etu efere, kpuchie efere, na-ere ahịa, na-ewepụta mgbanaka, ụlọ |

| D21 | Duclele ígwè | Etu efere, kpuchie ya, ụlọ |

| E05 | Carbon steel | Aro |

| C21 | Igwe anaghị agba nchara, 4cr13 | Strre uwe, Lantarnern, Lantern machibidoro, mgbanaka olu, gland bolt |

| C22 | Igwe anaghị agba nchara, 304ss | Strre uwe, Lantarnern, Lantern machibidoro, mgbanaka olu, gland bolt |

| C23 | Nchara nchara, 316ss | Strre uwe, Lantarnern, Lantern machibidoro, mgbanaka olu, gland bolt |

| S21 | BUPTy roba | Nkwonkwo ukwu, akara nkwonkwo |

| S01 | Roba roba | Nkwonkwo ukwu, akara nkwonkwo |

| S10 | Nitrile | Nkwonkwo ukwu, akara nkwonkwo |

| S31 | Hylelon | Debeller, Liners, REPELL RIF, na-ere, mgbaaka nkwonkwo, akara nkwonkwo |

| S44 / k s42 | Neoprene | Debeller, liners, mgbaaka nkwonkwo, akàrà |

| S50 | Vaton | Nkwonkwo ukwu, akara nkwonkwo |